Model No.︰-

Brand Name︰ZJN

Country of Origin︰China

Unit Price︰US $ 350000 / SET

Minimum Order︰1 SET

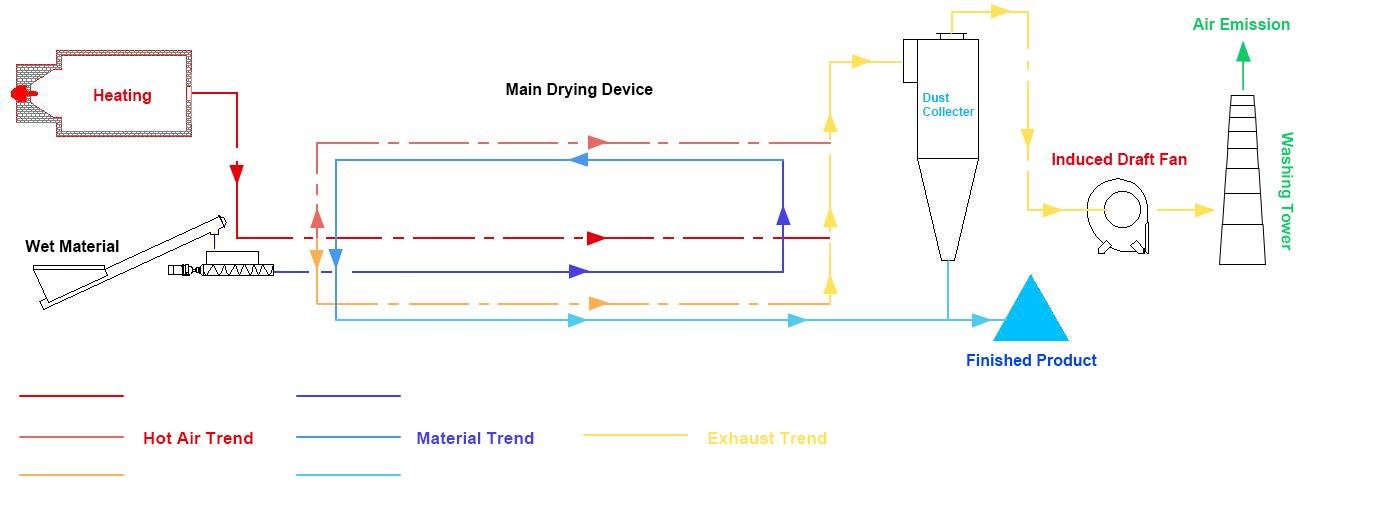

We have engineered a new-type rotary dryer that can treat 100+ tons of metallurgical waste a day

About us:

ZJN environment protection technology company manufactures industry-specific heavy-duty low-consumption rotary dryers widely used to dry,calcine,mill, grind, granulate, coat, de-volume and de-toxin wood chips(for bio-fuel), sawdust, sand, fertilizer, chemicals, kitchen leftovers, paper making pulp, animal feed, sludge in electroplating, leather, textile,printing and dyeing, coal mining and pharmaceutics,brewing, starch processing, biological fermentation, sewage, and hazardous metals, sweet potato residue, vinasse, bean dregs, medicine dregs, coal slime, lignite and others.

1. More than 30 years' experience.

2. We are the leading professional supplier of drying equipments and service for drying equipment industry.

3. All products achieved ISO9001:2008 quality management certificate and EU CE certificate.

Quality First, First Rate Service: strict quality control always, highly-trained personnel for all-round aftersales service.Three Guarantees policy for all our products.Our state-of-the-art design and strict quality control ensure reliable product quality.

Advantage of Rotary Dryer

(1). High production capacity

(2). Lower consumption and operation cost

(3) . Capable to dry different kinds of product

(4) . Stable operation

(5) . Uniform dried product

(6). Both dryer and calciner, operation Temp. Up to 1000°C

(7 ). Heat source can be steam, electricity, coal, natural gas etc.

Techs details:

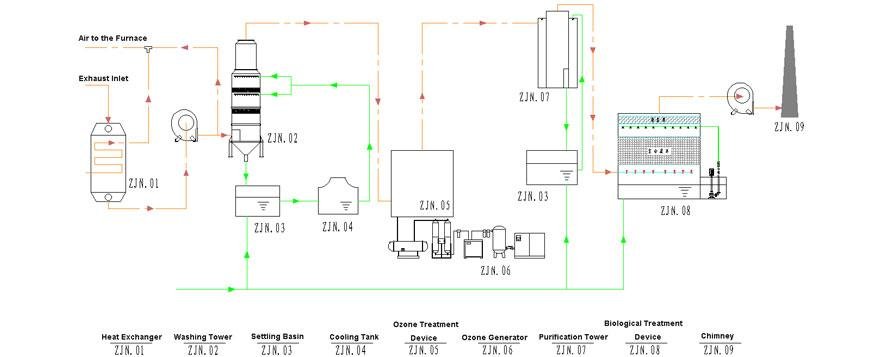

The Waelz process is a method of recovering zinc and other relatively low boiling point metals from metallurgical waste (typically EAF flue dust) and other recycled materials by a rotary kiln (waelz kiln).

The zinc-enriched product is referred to as waelz oxide, and the reduced zinc by product as waelz slag.

As of 2014, the Waelz process is the preferred or most widely used process for zinc recovery of zinc from electric arc furnace dust (90%).

Drying is a new way to recycle Waelz slag, turning the harmful steel mill waste material into a useful construction brick. Though there are concerns over the potentially toxic materials that could be leaked out of the bricks over time, these fears can be investigated and removed in the drying process.So, do contact for a dryer with us at affordable prices for an enoumous output and revenue in billions.

Payment Terms︰ TT/LC/DP/DA