Model No.︰-

Brand Name︰ZJN

Country of Origin︰China

Unit Price︰US $ 350000 / SET

Minimum Order︰1 SET

ZJN environment protection technology company manufactures industry-specific heavy-duty low-consumption dryers widely used to dry,calcine,mill, grind, granulate, coat, de-volume and de-toxin wood chips(for bio-fuel), sawdust, sand, fertilizer, chemicals, kitchen leftovers, paper making pulp, animal feed, sludge in electroplating, leather, textile,printing and dyeing, coal mining and pharmaceutics,brewing, starch processing, biological fermentation, sewage, and hazardous metals, sweet potato residue, vinasse, bean dregs, medicine dregs, coal slime, lignite and others.

More than 30 years' experience.

2. We are the leading professional supplier of drying equipments and service for drying equipment industry.

3. All products achieved ISO9001:2008 quality management certificate and EU CE certificate.

Quality First, First Rate Service: strict quality control always, highly-trained personnel for all-round aftersales service.Three Guarantees policy for all our products.Our state-of-the-art design and strict quality control ensure reliable product quality.

Advantage of Rotary Dryer

(1). High production capacity

(2). Lower consumption and operation cost

(3) . Capable to dry different kinds of product

(4) . Stable operation

(5) . Uniform dried product

(6). Both dryer and calciner, operation Temp. Up to 1000°C

(7 ). Heat source can be steam, electricity, coal, natural gas etc.

Techs details:

Tannery/leather/fur sludge is a solid waste that needs to be carefully managed, because it contains a lot of sulfur, chromium and other chemical substances, classified as hazardous waste. It should be particularly careful in sludge treatment equipment selection.

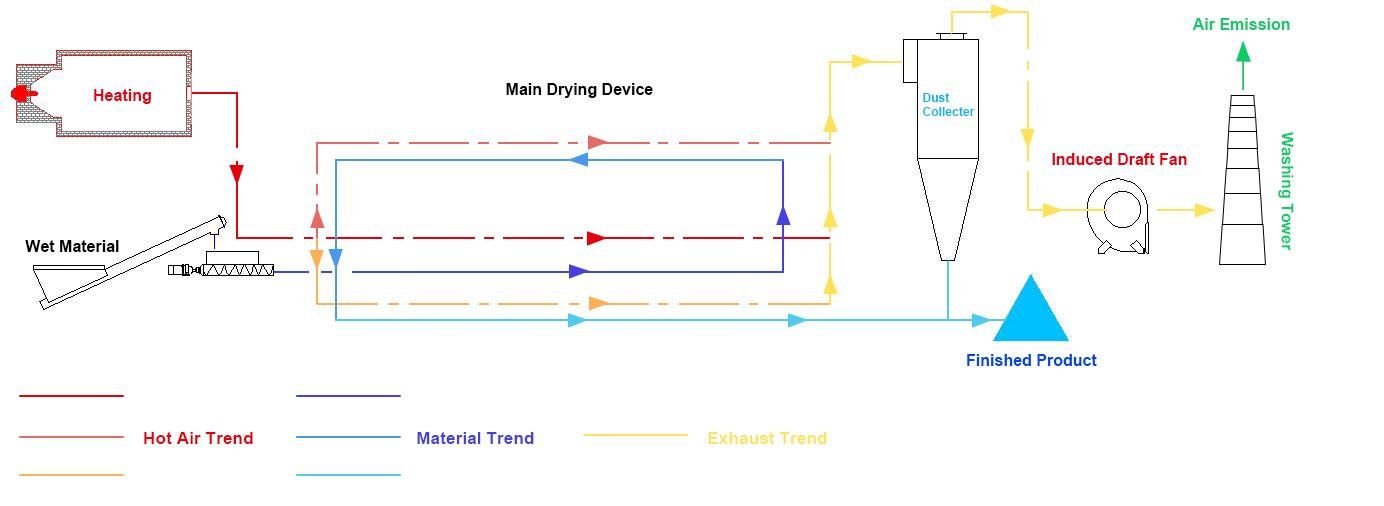

This ZJN drying machine is rotary drum dryer, with sludge directly and fully contacting with hot air, thereby speeding up drying processes. The waste water and air discharged are immediately, which can avoid the re-absorption. The dry sludge moisture content can be below 10%. The machine can work continuously for 24 hours per day. Only one or two operator is needed, so it's of low operating cost!

The dry sludge can be mixed with coal as fuel. After burning, all the harmful organic matter and pathogens in the sludge will be removed. It can protect the land and water resources from pollution. In addition ZJN drying equipment is equipped with dust removal equipment, which can handle the dried toxic and harmful substances. Dry sludge can also be used to make building materials.

So, negotiate and buy an affordable dryer to turn your waste into marketable goos while protecting the nevironment.

Payment Terms︰ TT/LC/DP/DA